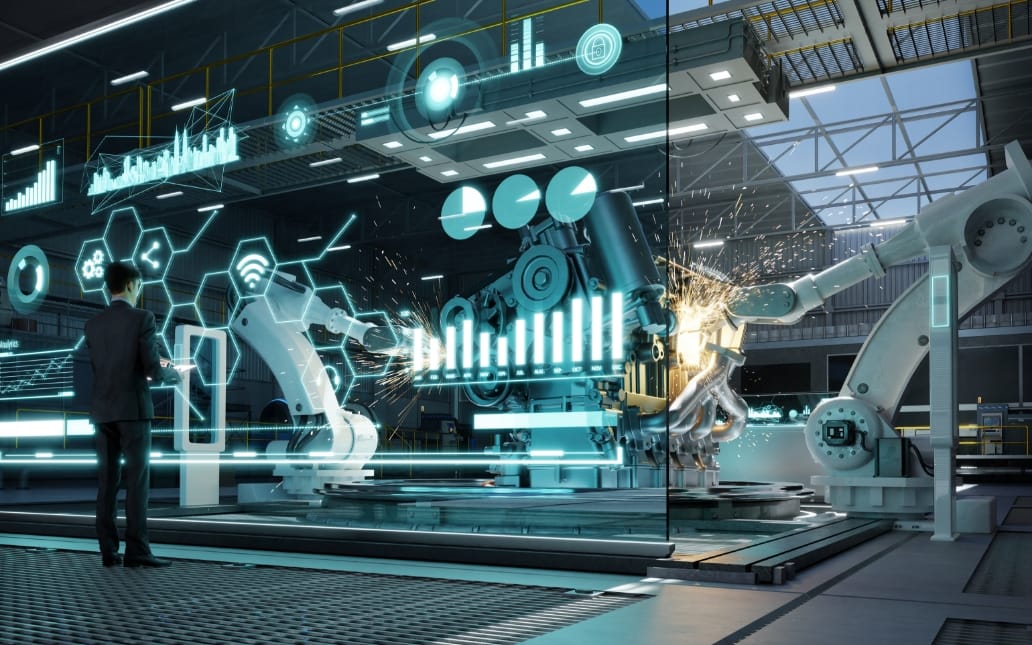

Digital twin platform

supporting optimized and advanced production plans through building virtual manufacturing sites and running what-if simulations

This digital twin platform integrates and connects the legacy systems as well as MICUBE Solution’s smart factory and manufacturing Intelligence solutions to build the manufacturing data pipeline that integrates and synchronizes P4R (Product, Process, Plan, Plant and Resource) snapshot information.

Based on the above, the what-if simulation running on ever-changing manufacturing data establishes optimal production plans based on the digital twin platform in synch with the site and proposes the best alternative for production and distribution management as well as supporting flexible and robust decision-making.

The manufacturing digital twin platform for designing and building the system of Advanced Planning and Scheduling (APS).

Optimized Production Scheduling based on What-If Simulations

Heuristic algorithm-based prognosis and optimization taken into account on-premise constraints and logics

Simulation-based KPI Predictive Analysis and Visualization

KPI prediction and customized dashboards that shows the rate of meeting deadlines and equipment operation rate through system integration

Automated Digital Twin Model Generation and Management

Minimized user’s input with data pipelines and integrated exchanges of standard-based automated data

Various Development Environments Supported

On-premise, cloud, and other services suitable for customer’s development environment

MICUBE Solution provides you with the best tailored solutions for you.

-

On-site restrictions and logics taken into account

heuristic algorithm-based

scheduling optimization -

What-If simulation-based

KPI computation and analysis

and customized dashboards -

Responses to issues within the supply chain via fluctuating event detection

and process reconstruction and optimization